Case Erector

The RECOPAK Automatic Case Erector range are an inline style machine which are designed to supply erected bottom hot melt sealed cases on demand.

Stainless Steel construction promotes an aesthetically pleasing appearance as well as satisfying the standard requirements of the food industry.

The design allows easy operator access to both sides of the machine, featuring electrically interlocked gull wing guarding.

A simple horizontal style case magazine makes it easy for operators to load. As an option, an extended capacity magazine provides longer running times without operator interaction.

The functional design of this machine makes format changes quick and simple.

hot melt hopper system is mounted at a convenient working height for refilling.

The cyclic motion case transfer system increases reliability, reduces maintenance and machine downtime.

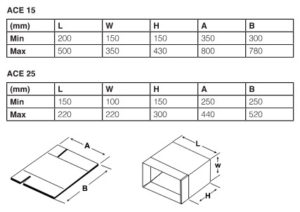

The RECOPAK AUTOMATIC Case Erector is designed to automatically erect and bottom hot melt seal most common RSC & HSC style case blanks, on demand or cycle continuously at speeds of up to 25 cases per minute (depending on the size of the case).