Fully Auto Case Over Product Packer

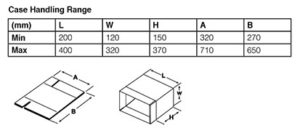

The RECOPAK fully automatic Case Over Product Packer (Fully Auto C.O.P.) offers our customers the most advanced R.S.C. case packing machine in our range.

Due to its modular design, a variety of infeed systems are available to suit the specific requirements of our customers.

The infeed system groups product into the required format and indexes individual groups onto the infeed shuttle conveyor.

As the product group enters the case packing section, a case blank is squared and pulled down over the product. The bottom inner flaps are folded automatically prior to the flight bar transferring the carton through the top flap closing and gluing sections.

The operator interface boasts a 10” colour touch screen fitted into a stainless steel swivel mounted enclosure. Product formats and operating parameters are easily selected and modified from the screen, which also displays machine status, product statistics and onscreen operator instructions.

The HMI rotates about the centreline of the machine to provide operator control from either side of the machine.

Full size guard doors on both sides of the machine offer complete access for operator intervention.